- #Cnc usb controller mk1 mach3 manual

- #Cnc usb controller mk1 mach3 software

- #Cnc usb controller mk1 mach3 code

- #Cnc usb controller mk1 mach3 Pc

I personally use Mach as the support is probably the best without being a total geek or relying on one man. Planet-CNC as already mentioned, and a couple others I can think off just now, but I've just had a complete mind blank over there names! One is UK based, and one US.

#Cnc usb controller mk1 mach3 software

Mach and LinuxCNC are the main two software packages with good support, but there are other options. Also: cable tie the bejesus out of the thing no cable should be able to move of its own free will. Don't put signalling cables (limit switches, etc) right next to power cables. Use cable that can take the current, and get shielded if you can afford it.

Just gotta cut slower I guess Just a tip: wiring matters a lot. I've got a rather large CNC router based on roller chain and steppers and you really can't do anything once you lose a step because you don't know until the job is finished. The best thing I have seen with linux is the mesa FPGA cards: and the best with mach3 is the smoothstepper: I have one of those usb things you have linked to, never was able to get it working all that well (but I didn't try very hard tbh because the parallel port turned out to be fine) I am building a new 3 axis machine with servos/encoders/geckodrives and a smoothstepper. If you don't want that, you need to decide if you are going for linux CNC or mach3 as it changes things. As mentioned, parallel port is usually a pretty solid choice as most stuff supports it (and it's super cheap/free). They are a lot more complicated than you think I tinker a lot with diy cncs. Support for advanced G-code - G54, G59.Well, my first CNC was supposed to be 'just a tool'.

#Cnc usb controller mk1 mach3 code

Support for advanced G- code - G40, G41, G42 (tool radius compensation )Īdvanced G- code - G43, G49 ( tool length compensation ) RS274/NGC G code (EMC2 compatible with standard ) You can start, stop, pause, and resume execution of the program on your computer Output Input buffer for maximum performance

#Cnc usb controller mk1 mach3 Pc

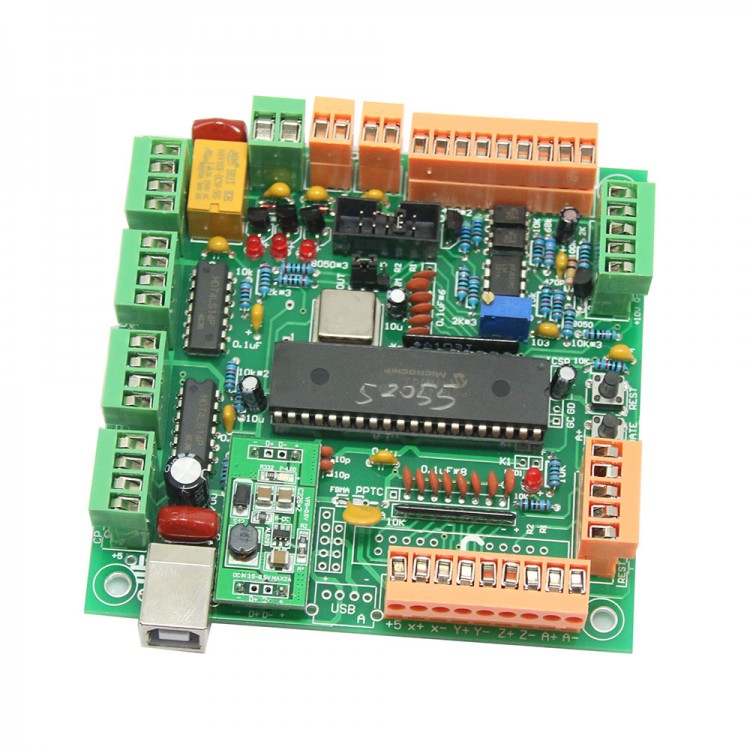

In order to stabilize, increase 7pcs diode, 10pcs electrolytic capacitor, 7pcs 104, 1pcs 103, 1pcs 102 capacitor and 2pcs 4700P / 250V capacitor.Ĭan run on Windows XP, Vista or Windows 7 (32 -bit or 64-bit PC / laptop USB port (2.x version ) )Ĭan be used in pulse / direction stepper motor and servo motor drives on the market Increase in power since the restoration of insurance to protect your computer.

#Cnc usb controller mk1 mach3 manual

You can control the drive completely isolated.Īn external manual interface, it is easy to connect external took control box. Using a 40-foot strip microcontroller, easy maintenance and replacement.ģ output ports with indicating, outside device is controled by the relay the directly. Costs increased, but a stable and reliable.

0 kommentar(er)

0 kommentar(er)